The Gibson Recording Amp seems to have originally had radial capacitor that was a triple capacitor, having the vaues of 22/20/20 UF and rated at 450 volts. In investigating the possible causes of the low frequency wall-rattling rumble it seemed more and more likely that all or part of this triple-capacitor was not functioning properly and was letting higher frequencies through to the amplifier. This was a rumble that you knew to shut down the amp immediatly because it would grow quickly and threaten to blow out the speakers.

I had questions about replacing it becasue I could not find any source of electrolytic capacitors like this. You can see this capacitor below, which looks like a paper coin wrapper. I you look closely you can the tube has been distorted by the spring steel clamp that holds it.

I searched quite a bit, but I could not find a source for capacitors like this old radial electrolytic, which was apparantly a triple-capacitor. The best solution I could come up with was to replace it with a can type capacitor that was a three or four in one. I cut out the old cap. I wanted to remove the rivit which attache the cap holder but it was backed by the choke. The two nuts that held the choke in place were difficult to reach and spun when I tried to remove the bolts from the outside of the case. I fnally found a way to hold them from spinning and got them free but it was tedious. I used a new rivit to install a holder for new capacitor and there was just barely enough room to squeze it in amon the existing wiring.

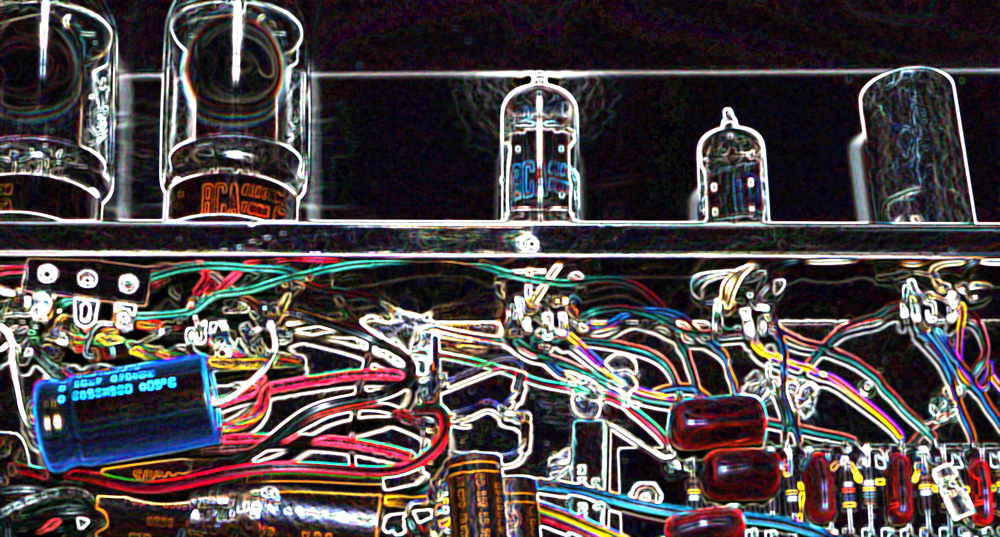

I had to extend the wiring to allow it to reach to the new cap. Here is a picture of how it looks installed:

Not shown here is that I used rivits to secure the choke back to the amplifier case. This was much easier than trying to fit in the old bolts and also felt like a more sturdy installation. If I have to remove the choke again it will be easy to drill out the rivits from the outside of the case.

Values: The values of the old triple capacitor was 22/20/20 uf 450 Volts. The new capacitor is a quad and is rated at 40/20/20/20 500 Volts. I opted to try the 40 to replace the 22 uf. Its’ my understanding that this may increase the bass and it’s better to go to a higher than a lower value than before. If I’m not happy with the sound I may switch it to a 20 uf post (so I have an option either way).

I must say, it was very satisfying to start up the amp and to find that the low rumble in 2nd and 3rd “ON” positions was completely gone.